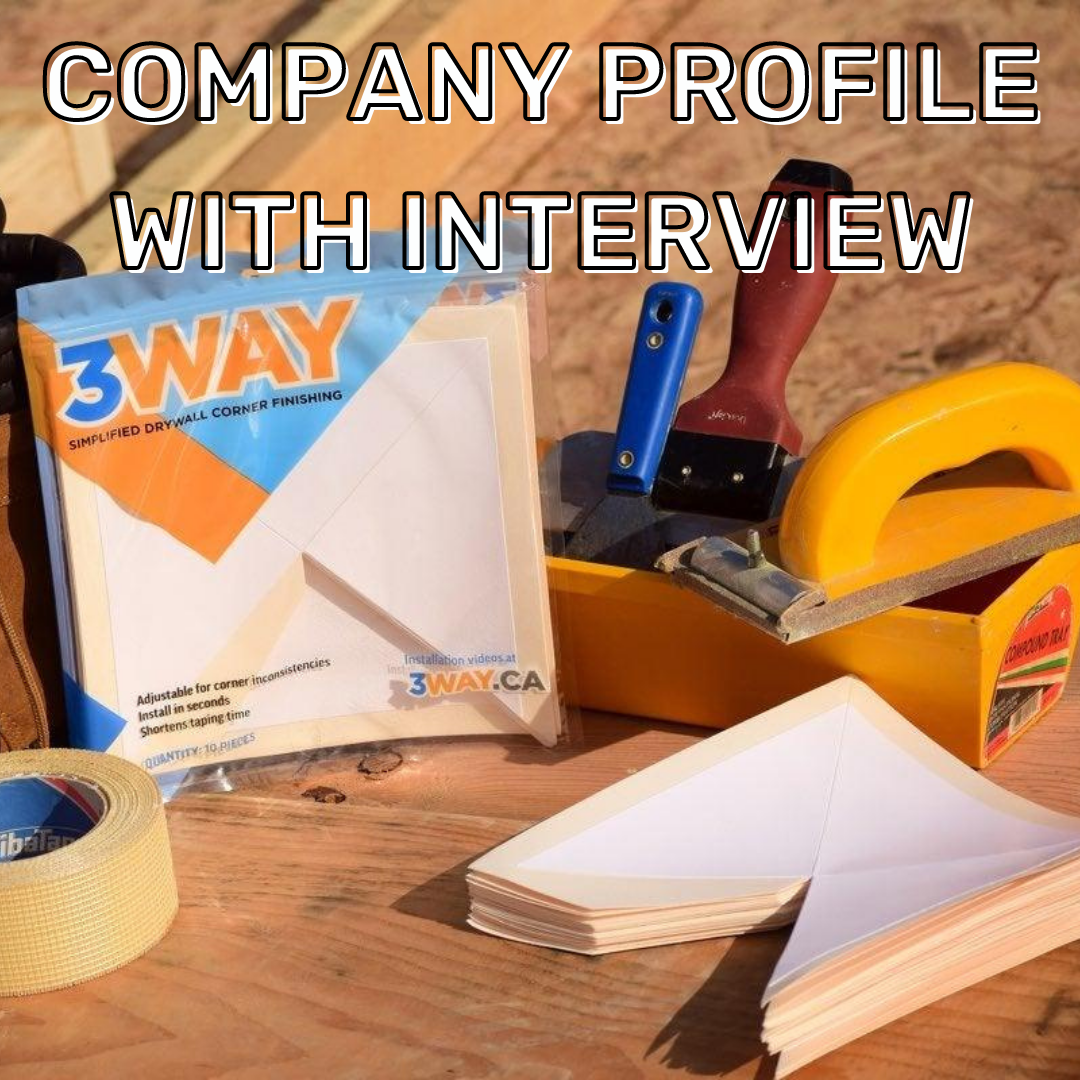

3Way is a revolution in the drywall industry completely changing the way tapers finish 3 way corners. A three way corner is as it sounds when three parts of a piece of drywall meet to create a corner. For example, two walls and a ceiling. This example is the most common three way corner.

Ever since drywall was first rose to prominence in the early 1900s corner finishing has been a difficult task for both beginners and professionals. The frustration of corner finishing comes from both the difficulty of the task, as well as, a lengthy process to complete the finish. 3Way solves both these problems by speeding up the process and making the task easier for both journeymen and novices.

We had the opportunity to interview Royce and Steven and get their story behind the creation of 3Way.

Who is Royce?

Royce is no stranger to the trades, given he has specialized in high end level5 drywall and paint finishing for over thirty plus years. He started out as an old school apprentice and worked his way up to slinging mud with absolute precision. Royce has influenced the industry in a number of ways over the years. Not only does he take on his own apprentices to learn the trade, but he also successfully raised five boys who can drywall with ease too.

What Inspired Royce to Create 3Way?

Did you know that in a standard subdivision home, completing three ways equates to 25% of the work and an average room with a closet has 8 corners to finish. The procedure to finish a 3-way corner is six stages involving a multi-layer multi-step process to achieve a perfect corner. For an industry pro, it often takes them years to craft and refine their skill, especially when they encountered builds where walls were not square or repairing cracks in older structures. For a Do-It-Yourself home renovator, this process can be extremely frustrating and sometime near impossible to get even close to a superior finish.

Over the years, Royce saw journeymen struggle trying to tackle challenging 3-way inside corners fiddling with 3 pieces of paper tape and drywall mud. He thought to himself, there must be an easier and faster way to reduce the steps and time involved while allowing others to become proficient at finishing three-ways. Plus, when you are in business for yourself, who doesn’t want to find a new way that improves your bottom line.

He was aware of several products on the market already available to help finish outside corners, but he could not find any solutions for the inside corner. Royce started to experiment with various shapes, sizes and designs to see what would work best in the field.

What are some challenges that you overcame in creating 3Way?

Royce said “Everybody has to start somewhere, and I found myself sitting in my kitchen like a kid in school with paper, pencil, ruler and a pair of scissors cutting out the same shapes many times” he laughs. “I was truly surprised at the struggle it was to create my vision for the 3WAY. He eventually grew this one-man show to a team of 4. With the expansion of more manpower and lot’s of brainstorming we shifted our focus to making 3WAY using a die-cut machine which allowed us to produce much more product in a day. Sourcing paper that would be up to the task was one of the hardest pieces we had to over come.

Our first design to hit the market for feedback and testing was a 3WAY that you would dip into water to activate the water activated glue on the back to apply into the three-way drywalled corner. We have since moved away from this installation method and use drywall compound. Like many products on you find on the market adding new features attracts more buyers. A lot of research and development happened over the last 2 years to really refine the 3WAY you can find in stores today.

“How could I have forgotten to mention about the long and tedious patent process” Royce exclaims. “I am used to dealing with homeowners and foremen not lawyers. I could not have done any of this process or all the administrative pieces without my friend and Chief Executive Officer Steven. Royce said “it is so exciting to see something you knew could be an industry game changer come to a reality and hear about it being used in the industry. We’ve been receiving lots of positive feedback from first time users and have noted many repeat buyers”.

3Way has changed the way tapers handle inside corners are there any plans to disrupt how outside corners are done?

Given that there are already several products that exist specifically for outside corners, we’re going to stick to what we do best, creating the perfect inside corner.

Any plans for future products?

Actually yes, 3WAY is currently working on a few things right now. Currently 3WAY are being sold in a 10 pack and a 25 pack. We have recognized that a Do-It-Yourself home renovator might only need a few to complete their project, therefore we are brining to market a DIY 5 pack. We are currently doing some re-branding of our packaging so we anticipate the new size should hit stores within the next few months.

Having put many a 3WAY in, we quickly realized that when you’re up a ladder or on stilts you of course want all of your tools by your side and within reach. We have since devised a clip-on pouch that is designed to hold a handful of 3WAYS. We tried out a few different versions to see what style worked best. We have just started the manufacturing process for our carrying pouch and suspect it should be available to our customers in the next few months.

Royce said “I have a number of ideas for future products as my mind is always thinking of ways that would allow a person wanting to take on their own little reno or a handyperson who is not a professional taper complete projects with a quality finish”.