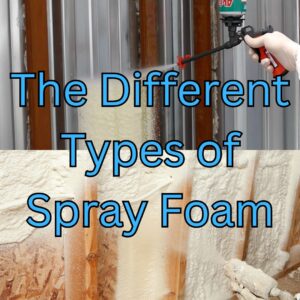

Spray foam insulation is considered one of the more customer-friendly insulation solutions. Various sorts of insulation can be utilized throughout a build. You can see all of the insulation materials we use in our materials tab.

There are a few upsides and downsides between each kind, however, these minor changes can be for the most part overwhelmed with the right installation method. This starts with understanding what insulation does, and what elements can influence the installation process.

Insulation is intended to forestall heat transfer. The ultimate goal when installing insulation is to ensure that heat either remains inside or outside of the structure depending upon the season. Heat transfer mainly occurs in the summer and winter months and is a significant supporter of energy loss increasing your heating and cooling bills. Stopping the dynamic of heat transfer is the point of insulation. Whether a building is insulated with fiberglass batt insulation or spray foam insulation it decreases energy use and saves funds on utilities all while providing indoor comfort.

Fiberglass Batt Insulation vs Spray Foam Insulation

Fiberglass batt insulation is by a long shot the most widely recognized home insulation in North America. It’s impressively less expensive than spray foam insulation. However, this doesn’t mean fiberglass is a low-quality solution. On account of its many credits, spray foam insulation is becoming a more popular insulation solution, and is turning out to be more common when installing insulation in small hard-to-reach places. For the overall construction of a home, these two insulation methods achieve the same goal. We will now examine the similarities and differences in the following sections of this article.

Cost of product and installation

Fiberglass batt insulation is most commonly sold in pre-cut standard sizes making for a simple installation into wall studs, loft rafters, and roof joists. Fiberglass batt insulation is generally more affordable than spray foam in the long run. To receive the absolute best maximum performance in insulation, you may consider a method known as air fixing. Air fixing can be achieved with a mix of both fiberglass and single-component foam insulation otherwise known as the ‘streak and batt’ approach. This approach incorporates both polyethylene sheets and caulking or liquid-applied air fixing. Assuming that the development is new, there are more choices accessible to expand its adequacy.

Spray foam insulation requires more work for installation than fiberglass batt subsequently making it more costly. Spray insulation requires more skill to apply correctly including the correct use of PPE.

R-Value: What is it?

Compared to other insulation solutions, spray foam insulation offers the most noteworthy R-value per inch. Since spray foam will provide a complete seal and insulate a building entirely. Spray foam can be closed-cell or open-cell. Open-cell is generally R-3.5 to R-3.6 per inch, and closed-cell is normally around R6 per inch. Akfix’s latest thermal & acoustic foam offers an R-value of 5.66.

Both fiberglass batts and loosefill fiberglass offer good R-Values when expertly installed. In any case, there might be a deficiency of thermal protection over the lifetime of loose-fill fiberglass on the off chance that it isn’t expertly installed. This could influence energy effectiveness over the lifetime of the structure and can require a fix by topping up the loosefill. These kinds of issues might be moderated by working with an expert. Moreover, an expert will assist with guaranteeing that precautionary measures, for example, air fixing are performed in advance. Fiberglass batts and loosefill can provide R-value up to 4.3 per inch.

-

Akfix Thermcoat Thermal & Acoustic Insulation Pu Spray Foam

Rated 0 out of 5Finishing Materials CAD $29.99 – CAD $359.88

Seal and air barrier

One of the critical properties of spray foam insulation is the ability to seal a space completely. Spray foam insulation makes an air barrier and insulation barrier simultaneously. It stops heat transfer, decreases the chance of mold and expands the energy effectiveness of your home. With fiberglass batts, making an impermeable seal requires extra work. Since the batts don’t normally give an air seal, introducing a different air boundary to finish the work is essential.

Energy Efficiency

Spray foam insulation offers extremely high energy-effectiveness results due to its inherent ability to provide a quality R-value and air-fixing combination. With better R-Values and better impenetrability, spray foam insulation provides cheaper warming and cooling costs and provides an adjusted well-balanced central air and climate control system execution. These factors lead to spray foam insulation enhancing indoor comfort no matter the season.

With fiberglass batt insulation, introducing a high-thickness item can give much better energy productivity when space is restricted. With the right establishment method, fiberglass batts additionally do their part in keeping your home cool throughout the hotter months and warm throughout the colder months.

Moisture and vapour barrier

Once introduced, spray foam insulation proceeds as a vapour barrier. However, not all spray foam insulation can be used for this purpose. Make sure to follow any building codes provided by your municipalities when considering using spray foam insulation and contemplate the prerequisites required for insulation.

Due to the nature of fiberglass batts, this type of insulation does not make a vapour barrier. When installing fiberglass insulation you should incorporate an additional layer of material for a vapour barrier.

Thermal Barrier

Whatever the structure is being built, the issue of the thermal barrier requires significant thought for each point of entry. With spray foam, this requires a unique use of thermal barrier material to be applied over the uncovered insulation. Once the thermal barrier is installed, you can expect the safety level to be equal to other sorts of insulation as far as fire is concerned. However, there is now spray foam insulation from Akfix that provides thermal insulation and acoustic insulation in the same can.

Fiberglass is either normally heatproof or treated with a fire retardant. Fiberglass, similar to spray foam, can be used for various applications in both new construction and retrofit applications. Whether it’s being blown into an upper room, or firmly positioned into wall cavities, appropriately introduced fiberglass insulation furnishes you with a protected home.

Picking the right insulation material for the job

In a decision on fiberglass batt protection or spray foam insulation, it is important to consider all factors. From R-Values to air entrances to air moisture, to whether it’s a new or retrofit build, everything needs to be evaluated. The point is to find what is the absolute best investment for the long term.

Insulating a house is tied in with making a comfortable indoor living arrangement. The goal is moderating energy, and saving money on utilities throughout the year. While homeowners may find a way to deal with insulation, we feel you ought to gauge the difficulty of installing your insulation and consider an expert for your job. Regardless, if you decide to install insulation on your own we believe foam insulation may be easier to install on your own but you may end up spraying incorrectly and leaving a draft somewhere in the home. At the same time, installing fiberglass batts can be more difficult to install accurately. The outcome you are ultimately looking for is an energy-efficient home.